This Smart News Release features multimedia. View the full release here: http://www.businesswire.com/news/home/20170418006703/en/

Stable and highly precise control is a basic operating requirement, for motors used in printers, office appliances, banking terminals such as ATMs, cash dispensers, amusement machines, and home appliances. Recent demand has also emphasized more efficient motor drivers that use less power and generate less heat generation.

Avoiding stalls in stepping motor operation is the highest priority for securing stability and precision in motor control, and is achieved by provision of additional current to assure an operating margin for the motor. Real-time monitoring of motor torque and current feedback, using additional sensors and highly advanced MCU control, are also required to improve efficiency and heat generation.

A further way to improve efficiency and cut down heat generation is to adjust the built-in MOSFET's on-resistance and cut down power loss during operation.

The TB67S289FTG is the first stepping motor driver to apply Toshiba’s original anti-stall and efficiency improvement system, Active Gain Control (AGC)[1], which enables the driver to monitor the motor and torque, and automatically optimizes motor control without additional MCU control. In operation, TB67S289FTG prevents motor stalls and automatically optimizes motor current, depending on torque needed. Compared with current solutions, TB67S289FTG cuts down the motor power by up to 80% at best, winning significant improvements in efficiency and heat improvement without relying on on-resistance.

Further efficiencies can also be achieved when the new stepping motor driver is supported by ACDS[2], Toshiba’s sense-resistor-free current monitor and control system, which allows more free space and uses fewer external components on the PCB.

Toshiba positions the TB67S289FTG as its flag-ship stepping motor driver, a high performance motor control and component reduction solution, and will continue to expand its line-up.

Main Features

1. Anti-stall and high efficiency

Toshiba’s new motor control architecture AGC for anti-stall and high efficiency motor control. Plus sense-resistor-less current control ACDS for additional PCB space. High-resolution 1/32 step (max.) motor control cuts down noise and vibration.

2. Lower heat generation

Heat generation is reduced by low on-resistance (0.46 Ω (upper + lower: typ.)).

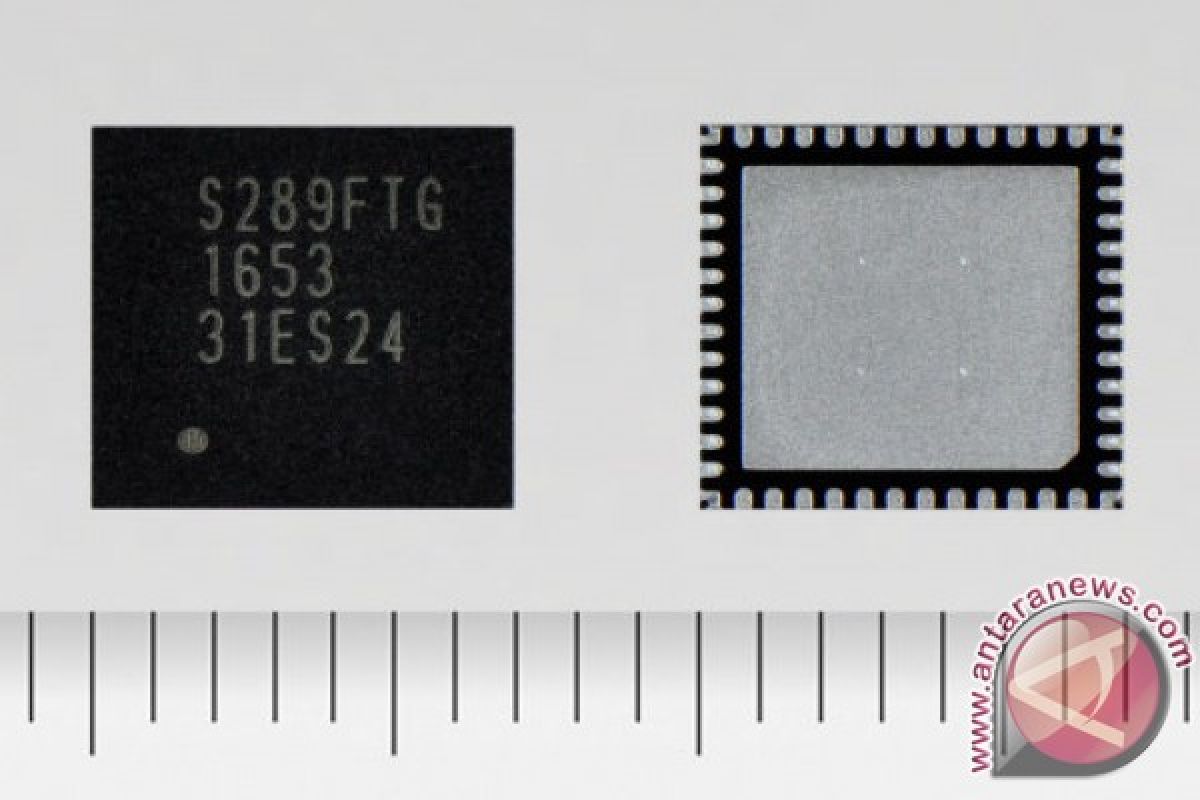

3. Small package

Packaging in a small QFN package allows customers to reduce heat problems and simplify PCB design patterns for heat dissipation. It will also realize affordable solutions in terms of space and cost.

4. Built-in error detection circuits

Thermal shutdown, over-current shutdown, under voltage lock-out and motor load open detection circuits contribute to equipment safety and reliability. Also, error status can be flagged to MCU using error flag function.

|

Main Specifications of New Product

|

||

| Product name |

TB67S289FTG

|

|

| Control I/F |

|

CLK-IN

|

| Absolute maximum ratings |

|

50V, 3A |

| Package |

|

QFN48 |

| Step resolution |

|

Full, Half, Quarter, 1/8, 1/16, and 1/32 step resolution |

| Other features |

|

- AGC; a current control method for anti-stall and high efficient

motor operation - ACDS; a current control method which does not require sense resistor - Built-in error detection functions (thermal shutdown, over-current shutdown, under voltage lock out, and motor load open detection) - Built-in error detection signal output function - Supports the power-on sequence by the single power drive |

| Mass production | End of July, 2017 (scheduled) | |

[1] AGC: Active Gain Control. Motor control architecture that optimizes motor current to torque while preventing motor stalls.

[2] ACDS: Advanced Current Detection System. A motor control architecture that does not require an external sensing resistor to monitor the motor current.

Note: Motor stall: When motor rotation deviates from the control signal, stalling occurs and the motor stops rotating.

For more information about the new product, please visit:

https://toshiba.semicon-storage.com/info/lookup.jsp?pid=TB67S289FTG®ion=apc&lang=en

Customer Inquiries

Mixed Signal IC Sales and Marketing Department

Tel: +81-44-548-2821

https://toshiba.semicon-storage.com/ap-en/contact.html

*Information in this document, including product prices and specifications, content of services and contact information, is current on the date of the announcement but is subject to change without prior notice.

About Toshiba

Toshiba Corporation, a Fortune Global 500 company, channels world-class capabilities in advanced electronic and electrical product and systems into three focus business fields: Energy that sustains everyday life, that is cleaner and safer; Infrastructure that sustains quality of life; and Storage that sustains the advanced information society. Guided by the principles of The Basic Commitment of the Toshiba Group, “Committed to People, Committed to the Futureâ€, Toshiba promotes global operations and is contributing to the realization of a world where generations to come can live better lives.

Founded in Tokyo in 1875, today’s Toshiba is at the heart of a global network of 550 consolidated companies employing 188,000 people worldwide, with annual sales surpassing 5.6 trillion yen (US$50 billion). (As of March 31, 2016.)

To find out more about Toshiba, visit www.toshiba.co.jp/index.htm

View source version on businesswire.com: http://www.businesswire.com/news/home/20170418006703/en/

Contacts

Media Inquiries:

Toshiba Corporation

Storage & Electronic Devices Solutions Company

Chiaki Nagasawa, +81-3-3457-4963

semicon-NR-mailbox@ml.toshiba.co.jp

Source: Toshiba Corporation Storage & Electronic Devices Solutions Company

Reporter: PR Wire

Editor: PR Wire

Copyright © ANTARA 2017