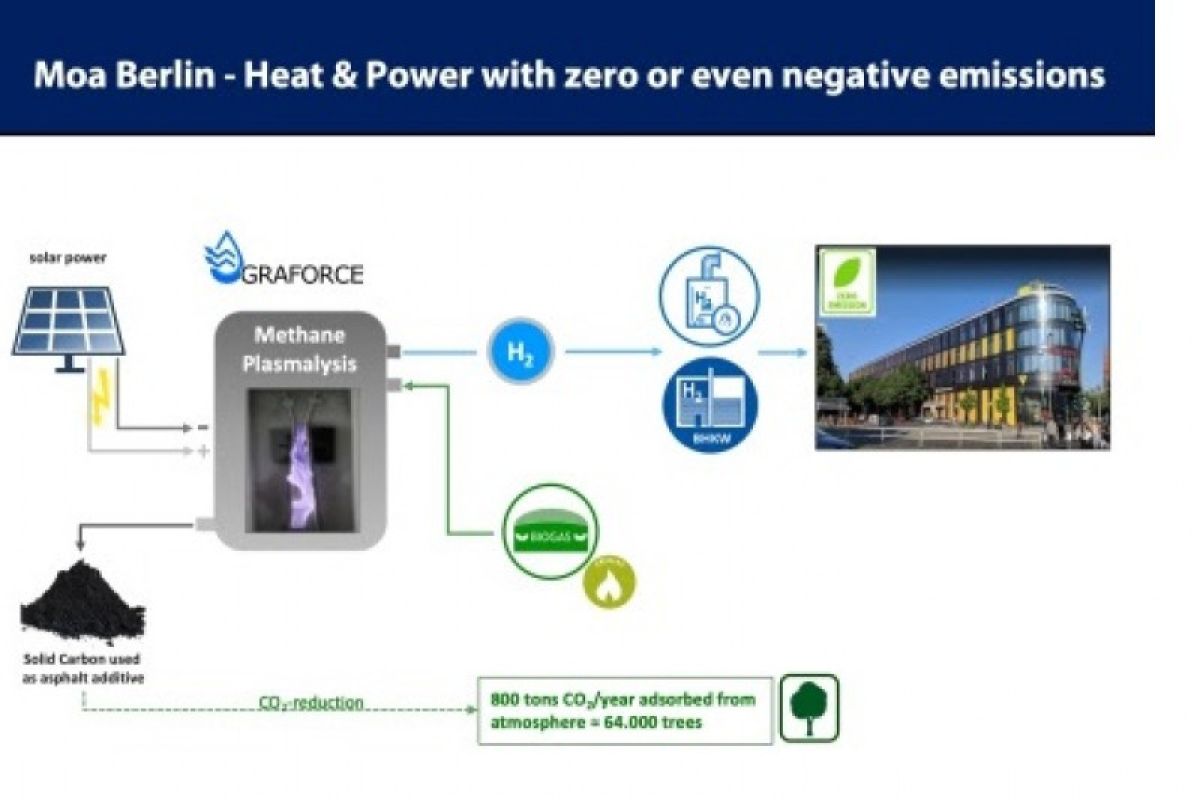

The MOA Berlin is no longer heating with natural gas but with hydrogen from biogas. The methane plasmalysis technology splits the biogas into hydrogen and solid carbon. Using electricity from renewable energies, methane plasmalysis is just as climate-friendly as electrolysis – but the costs are significantly lower.

For the zero-emission heating process, the MOA Berlin uses modified gas condensing boilers fueled by a mixture of green hydrogen and biogas. The mixing ratio is controlled by the methane plasmalyzer. The heat generation is started with 30 vol.% hydrogen and 70 vol.% biogas. In the following months, the share of hydrogen is gradually increased.

The solid carbon can be used as an industrial raw material, for paints and ceramics or, as in the case of the MOA Berlin, for producing asphalt. Thus, CO2 is permanently bound. Thus, Graforce offers the worldwide first market-ready technology for CO2 reduction and a green alternative to the controversial CCS storage.

The gas heaters used at the MOA Berlin before would have emitted up to 800 tons of CO2 per year. In order to absorb this amount from the atmosphere, the equivalent of more than 65,000 trees is needed.

"In order to counteract global warming, the generation of heat and hot water must be completely CO2-free by 2050. There are two ways to achieve this: Either we’ll heat with renewable electricity only or we decarbonize the natural gas supply with a carbon-free alternative such as hydrogen," Graforce founder and CTO Dr. Jens Hanke explains.

About

The German company Graforce has developed new plasma applications for inexpensively producing green hydrogen and other valuable industrial gases from residual materials. www.graforce.com/EN

Photos/Multimedia Gallery Available: https://www.businesswire.com/news/home/52324006/en

Contacts

Graforce GmbH

Dr. Jens Hanke

Phone: +49 30 - 63 2222-110

presse@graforce.deSource: Graforce

Reporter: PR Wire

Editor: PR Wire

Copyright © ANTARA 2020